HUASHENG is a leading expanded polyethylene foam supplier; our newly developed REPS is widely used across construction and industry and is suitable for fire retardant insulation, foam packaging material, and other applications.

REPS is a high-performance foam material widely used in foam packaging material and EPS construction material applications. Produced from modified polystyrene, REPS combines moderate toughness with versatile properties, suitable for projects requiring both strength and lightweight design. Standard expandable polystyrene beads range from 0.8 to 1.2 mm, while customized sizes enable refined structures or multi-layered solutions. Typical applications include tray-type products with a particle size of 0.65; HUASHENG’s independent design of REPS raw material production equipment enables multi-layered particle sizes of 0.8 mm. REPS is a better alternative to EPS construction material and foam packaging material, with production supported by HUASHENG—leading EPS bead suppliers and expandable polystyrene factory.

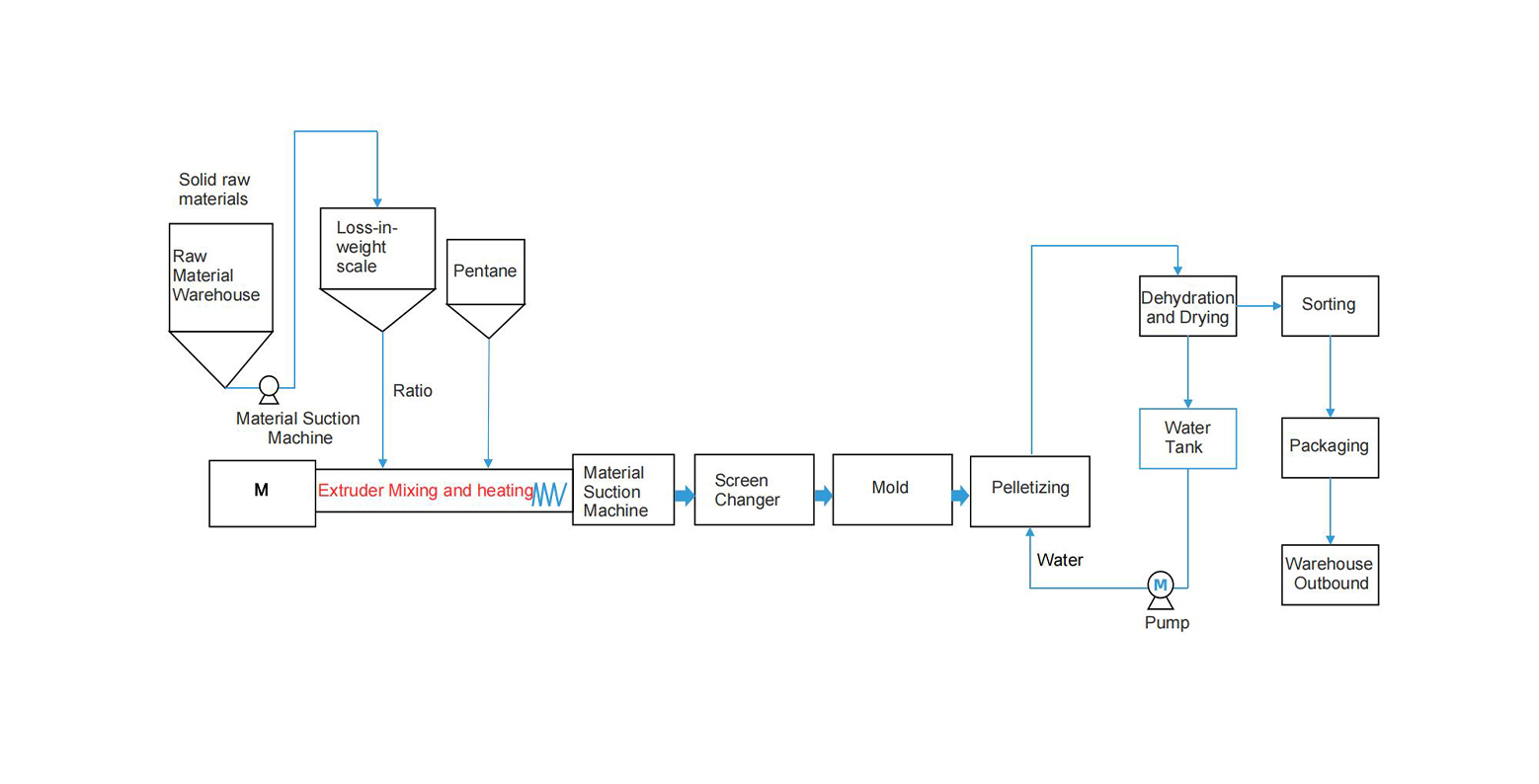

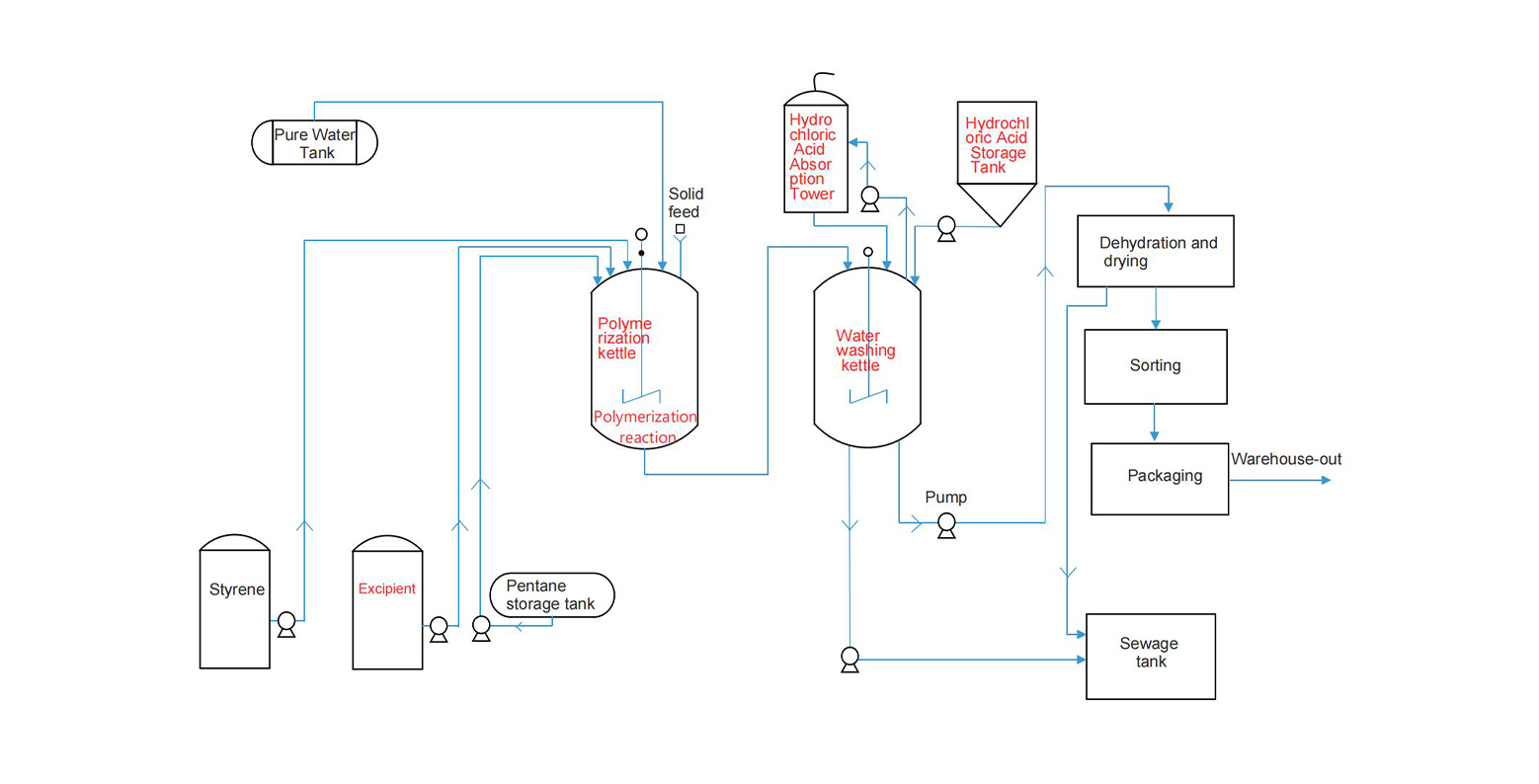

Discover the difference between REPS and EPS production progress. REPS is a strong and lightweight foam packaging material, perfect for packaging and transportation use.

Shows REPS toughness, strength, and stability for construction material, foam packaging, and polystyrene bead insulation.

| Project | Performance | Test Method (Standard Followed) | Unit | Magnification | |||

| Foaming Rate | 20 | 25 | 30 | 40 | |||

| 1 | Density | GB/T6343-2009 | g/L | 50 | 40 | 33 | 25 |

| 2 | Compressive Strength(10% deformation) | GB/T8813-2020Method A | kPa | 258 | 213 | 159 | 105 |

| 3 | Compressive Strength(25% deformation) | kPa | 301 | 252 | 194 | 130 | |

| 4 | Compressive Strength(50% deformation) | kPa | 382 | 328 | 264 | 180 | |

| 5 | Compressive Strength(75% deformation) | kPa | 664 | 588 | 495 | 327 | |

| 6 | Tear Strength | ASTMD624-00(2020) | kN/m | 1.7 | 1.3 | 1.1 | 0.7 |

| 7 | Flexural Strength | GB/T8812.1-2007 | kPa | 462 | 407 | 299 | 211 |

| 8 | Flexural Stress (5%) | kPa | 421 | 369 | 254 | 178 | |

| 9 | Flexural stress at maximum load | kPa | 462 | 407 | 299 | 211 | |

| 10 | Flexural strain at break | % | 7.7 | 7.6 | 8.6 | 9.8 | |

| 11 | Tensile Strength | ISO1926:2009 | kPa | 380 | 272 | 243 | 162 |

| 12 | Puncture Resistance | ASTMF1306-21 | N | 67.7 | 48.3 | 39 | 26.8 |

| 13 | Dimensional Stability23℃→(80℃)→23℃ | ASTMD1710-15(Reapproved2021) Section 12.5 | % | Length:0.43 Width: 0.29 | Length:0.39 Width: 0.34 | Length:0.38 Width: 0.37 | Length:0.48 Width: 0.42 |

| 14 | Dimensional Stability23℃→(-30℃)→23℃ | ASTMD1710-15(Reapproved2021) Section 12.5 | % | Length:0.10 Width: 0.10 | Length:0.11 Width: 0.10 | Length:0.11 Width: 0.12 | Length:0.16 Width: 0.15 |

| 15 | Water Vapor Transmission Rate | ASTME96/E96M-22aProcedureB | g/(m²·h) | 0.309 | 0.523 | 0.56 | 0.575 |

| 16 | Tensile Strength at Break | GB/T1040-2006 | Kpa | 558 | 548 | 440 | 265 |

| 17 | Elongation at Break | mm | 8.6 | 7.5 | 6.1 | 5.1 | |

| 18 | Poisson’s Ratio | ISO527-1-2019&ISO527-3-2018 | μB | 0.17 | 0.25 | 0.26 | 0.28 |

| 19 | Tensile Modulus of Elasticity | ISO527-1-2019&ISO527-3-2018 | Mpa | 23.9 | 16.3 | 13.2 | 8.47 |

| 20 | Compressive Modulus of Elasticity | ASTM-D1621 | Kpa | 9880 | 9216 | 6200 | 3135 |

| 21 | Bead particle size | QB/T4009-2010 | mm | 0.76 | 0.76 | 0.76 | 0.76 |

Highlights REPS’s customizable particle sizes and superior lightweight performance versus other foam materials.

| Project | REPS | EPO(PE+PSCopolymer) | EPS | EPP | EPE |

| Bubble structure | Independent closed cell | Independent closed cell | Independent closed cell | Independent closed cell | Independent closed cell |

| Mechanical strength | Medium | Medium | Brittle | Strongest | Medium、but soft |

| Maximum service temperature | 85℃ | 80℃ | 85℃ | 110℃ | 80℃ |

| Impact resistance | Good | Good | Bad | Superior | Superior |

| Toughness | Good | Good | Bad | Superior | Superior |

| Oil resistance and chemical resistance | Good | Good | Good | Superior | Superior |

| Water absorption rate | Low | Low | Low | Low | Medium |

| Recycling grade and difficulty of recycling | Level 6, equivalent to EPS | Difficult to recycle | Level 6 | Level 5 | Level 4 |

| Compressive strength | Good | Good | Superior | Bad | Bad |

| Bending strength | Good | Good | Bad | Superior | Superior |

| Heat resistance | Medium | Medium | Medium | Superior | Bad |

| Weather resistance | Medium | Medium | Superior | Bad | Bad |

| Dimensional stability | Superior | Bad | Superior | Bad | Bad |

| Moisture resistance | Superior | Superior | Superior | Superior | Bad |

| Non – flaking performance | Superior | Superior | Bad | Superior | Superior |

| Density range g/l | 22~50 | 20~40 | 5~50 | 20~60 | 30~60 |

| Price | Medium | Relatively expensive | Cheap | Relatively expensive | Relatively expensive |

| Cost – performance evaluation | The performance is equivalent to that of EPS, but it has flexible applicability, a low unit price, and a significantly high comprehensive cost-performance ratio. | The process is fixed, the unit price is high, it is non-recyclable, and the acceptance degree of end customers is low. | It has a wide range of application fields and a low unit price, but its performance is generally for low performance packaging. | It has superior performance and a high unit price. It is generally recommended for packaging high-value products. | The performance advantages and disadvantages are polarized, the applicability is limited, and the cost is onthe high side. |

HUASHENG is a professional EPS bead supplier; our charts demonstrate the statistics of REPS production progress, including raw material, pre-expansion, curing, molding, etc.

| Manufacturer/Process flow | Item | YXC(16.0)GPO |

| Raw material | Material | Modified expandable polystyrene resin (GPO) |

| Model specification | High-strength material (GPO) | |

| Supplier | Anhui Qiantai New Materials Co., Ltd. | |

| Pre-expansion | Temperature | 85°C±2°C |

| Time | Pre – expansion cycle: 100 seconds – 200 seconds | |

| Density | Lid and bottom: 40 times | |

| Curing | Time | 4-8H |

| Bin height | 10 m | |

| Single silo full storage | 450 molds | |

| Molding | Steam pressure | 0.55-0.85bar |

| Steam heating time | Mold transfer heating time: 6±3 seconds.Fixed mold heating time: 6±3 seconds.Main heating time: 7±3 seconds. | |

| Mold water cooling time | 1.0-5.0 seconds | |

| Vacuum stabilization time | 50.0-90.0 seconds | |

| Antistatic liquid | Manufacturer and model of electrostatic liquid | Guangzhou Jiamosen Environmental Protection Technology Co., Ltd.+SN/NMP-2208B/2218B |

| Coating method | Spraying | |

| Drying | Coating method | 50C±5°C |

| Time | 8H | |

| Air-drying | Temperature and humidity | Indoor environmental temperature(0-40~C/20%–80%) |

| Time | 24H |

Summarizes why REPS foam material offers better adaptability, toughness, and broader applications than traditional expanded polyethylene foam materials.

| REPS | EPS | Advantage Comparison | |

| Masterbatch Process | Physical method | Chemical method | The physical method replaces the chemical method to reduce the emission of three wastes. |

| Product molding | Pre-foaming + Molding | Pre-foaming + Molding | The comprehensive energy consumption for molding is saved by more than 20%, and the comprehensive molding efficiency is increased by more than 50%. |

| Project Application | Flexible | Relatively fixed | Customized production can be carried out according to specific products, optimizing performance and particle size, and enriching colors. |

| Recycling | Recyclable | Difficult to recycle | It complies with the international PS recycling category 6, can be used for export projects, and can be recycled internally for re – granulation or downgraded treatment. |

| Cost | Localization | Import | Localized production offers obvious cost advantages. |

REPS’s projects applied in the display industry include OC for TVs, module assemblies for monitors (MNT), and tray plates for notebooks, tablets, and OLED panels (NB, TPC, OLED). These applications are backed by extensive factory testing and real usage data, demonstrating REPS foam material versatility and reliability in practical production environments.

Copyright © Huasheng Qihang (Tianjin) International Trade Co., Ltd. All Rights Reserved